- Gestamp, Teltronic and Embeblue have launched a research project to establish a new operations model to improve the competitiveness of the industry through its complete digitalisation based on the use of 5G private networks and massive sensorisation.

- The main objective is to develop a communications system and virtual applications that, through 5G technology, will allow the plant to be controlled in real time.

- The initiative has been selected in the framework of the UNICO SECTORIAL 2023 programme

Zaragoza, January 18th 2024

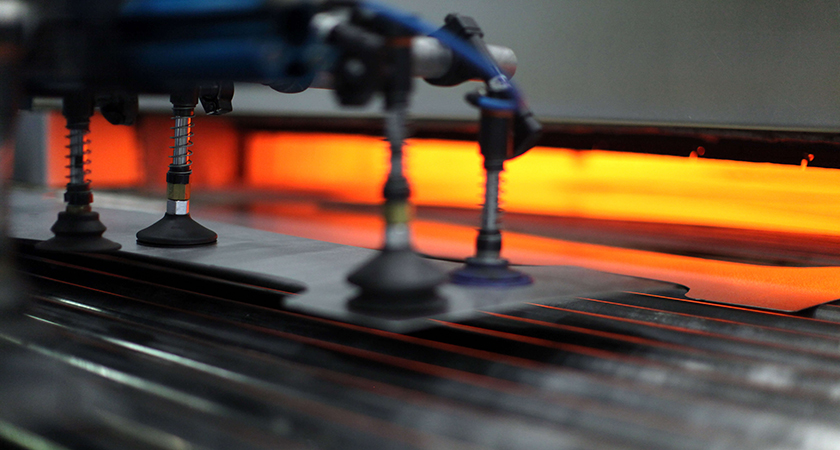

Gestamp, Teltronic and Embeblue have launched the R&D project INDUSTRY5.G – Development of industrial connectivity and applications over 5G for the virtual management of plant operations in the automotive sector, which aims to investigate a new operations model that, over private 5G communication networks and asset sensorisation, makes it possible to improve the competitiveness of the industry based on its complete digitalisation.

“The European and Spanish industrial sector needs to increase its competitiveness in the face of the risk of losing leadership to other regions. The only way for a competitive industry is flexibility in operations and the development of technology that allows for more resilient factories through a more agile, efficient and sustainable operations model with which to manage the uncertainty and variability that characterise today’s markets”, explains Jorge Vázquez, project coordinator for Gestamp, a multinational specialised in the design, development, and manufacture of highly engineered metal components for leading vehicle manufacturers.

In this way, INDUSTRY5.G aims to advance in the development of a new concept of “Smart Factory” that, using 5G private networks, 5G wireless sensor technology and evolved IOT devices, and virtual tools and models based on massive data ingestion and processing, will enable real-time control of processes, achieving flexible and autonomous manufacturing, and thus obtaining excellence in operations.

The automotive sector will be the testing ground for this research project. It is a strategic sector for the country, which between vehicle manufacturers and the components sector contributes 10% of the Spanish GDP and employs approximately 9% of the active population. Although the initiative aims to be a driving force to promote sector digitalisation and to be a benchmark in the automotive sector, the ambition is that the model can also be replicated in other industries.

To carry out all the capabilities of the new communication technologies and their adaptation to industrial environments, the development of the project will be articulated around three main axes. Firstly, the aim is to apply new connectivity models on private 5G networks that enable simple, flexible, and low-cost installation in industrial environments. In addition, work will be done on a standardised and interoperable solution that offers the required quality of service levels and implements cybersecurity measures.

Secondly, explains Mikel Meoki, founder of Embeblue, “a new massive IoT wireless sensor system will be developed specifically for the complex working conditions of industrial production plants, cyber secure, easy to deploy and with unified architectures and protocols; a technology not currently available on the market that provides flexibility and mobility for operations”.

Finally, for the orchestration of all the data generated, a digital tool will be developed, essential for managing the information flow of the production processes and, thus, monitoring factory operations. This virtualisation tool will make it possible to use the information to simulate possible scenarios to facilitate decision-making in real-time.

“These three axes expand the scenario of use cases in different verticals and 5G becomes a lever of transformation for the industry, with benefits not only concerning products and processes but also at the strategic level since the smart factory will convert large amounts of complex data into information that helps with crucial high-level decisions for the organisation”, says Alfredo Calderón, R&D director at Teltronic, who points out that the industry has a “unique opportunity” now that the National Frequency Allocation Table (CNAF) has reserved spectrum for self-provisioned networks.

The R&D project has a 33-month implementation period and has been one of the projects selected by the UNICO SECTORIAL 2023 programme, within the framework of the EU-funded NextGenerationEU Recovery, Transformation and Resilience Plan.

PARTICIPANTS

The INDUSTRY5.G consortium is made up of three Spanish companies that are leaders in their sector, complementary and of a marked technological nature. The project is led by Gestamp, a multinational in the automotive components sector, with the collaboration of Teltronic, a company with almost half a century of experience in the design and manufacture of communication systems, and Embeblue, an electronic engineering company specialising in electronic devices for the Internet of Things and Industry 4.